Centrifugal pumps are frequently operated in parallel to achieve higher system flows, to enhance system flexibility or to provide greater pump redundancy and hence better system availability. For very large projects, limited availability of sufficiently large pumps or limits on driver size or electrical starting current may dictate the use of multiple pumps. There are traps for the unwary. Simply running an additional pump in parallel may not provide the expected results.

In our last article Stable & Unstable Curves, we looked at what makes a centrifugal pump curve "stable or "unstable". We also discussed the importance of understanding your system and, in particular, how the system will only operate where the pump curve intersects the system curve, and the differences between "steep" system curves and "flat" system curves. These preceding concepts are absolutely crucial to understanding many of the issues associated with operating pumps in parallel.

To begin, we will define parallel operation and outline how to predict system performance when two or more pumps are operated in parallel. We will discuss selection rules for parallel operation and then look at how different system characteristics react to parallel pump operation.

Parallel operation

"Parallel" operation means that two or more pumps are operating with common inlet and outlet systems. This means that each pump will have the same differential head. The total flow is the sum of the individual pump flows. See Fig 1.

Predicting performance

To predict the system performance, a combined curve for all pumps can be produced by adding the individual flows from each pump curve at a common head. This is illustrated in Fig 2 below :

As with any pumping system, the system will operate where the combined curve intersects the system curve.

In this example, the Pump curves used are not identical and this highlights a likely serious operating problem. Because Pump 'A' has a higher head at zero flow, this pump will overpower Pump 'B' at low system flows. This is highlighted in Fig 3.

In this scenario, the pump with the lower head will be stalled, and assuming that a non return valve has been fitted, it will be running at closed valve with all the attendant risks and damage.

Matching pump curves for parallel operation – selection rules

The primary concern when running centrifugal pumps together in parallel is that pumps share the load safely at lower flows.

This does not mean that pumps must have identical characteristics. Groups of low flow pumps and high flow pumps are often operated together in parallel to match variable system demand. The aim is that all pumps have matching heads at low flow to prevent pumps being stalled or blocked in by the others.

- It is most important that the zero flow or "shut valve" heads are matched for pumps that will operate together in parallel.

- Unstable pump curves must be avoided for parallel operation, particularly where there is any chance of operation anywhere near their point of instability. Unstable pump curves present a very real risk of surging when operating in parallel.

- Steeper pump curves are preferred for parallel operation to assist with load sharing at low flows. Pump curves that are very flat at low flow are prone to wide flow variations with minor changes in head and may make load sharing difficult. See Fig 4.

4. Be aware of minor performance variations that may change the suitability of otherwise well matched pumps. If one pump has had more use and is worn, its curve may no longer match the other pumps. Pumps using different drivers such as a steam turbine driven pump operating in parallel with an electric motor driven unit may operate at sufficiently different speeds to cause mismatch of pump curves at low flow.

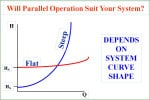

Will parallel operation suit your system?

This depends on what you are trying to achieve.

If the aim is to increase and decrease system flow by operating one, two or more pumps in parallel to meet changing demand then it is important to understand the type and limitations of your system.

If your system curve is relatively "flat"; ie. mostly static difference in levels and minimal pipe friction, then operating pumps in parallel will provide a useful performance variation.

If your system is mostly friction resistance (a steep system curve) such as a closed loop circuit or a lengthy pipeline, then performance variation will be minimal. This may be a good or a bad thing depending on what you are trying to achieve.

Flat system curves

Refer Fig 5.

When the system resistance is relatively flat (not much friction), operating additional pumps in parallel will produce a useful flow increase. Incorrectly, many operators expect that flow will double if two pumps are running in parallel. This cannot happen because, when added together, the combined pump curve intersects the system curve at a higher head due to increased frictional resistance and hence each pump will be operating at a higher head and lower individual flow than when operating alone.

Steep system curves

Refer Fig 6.

When the system curve is steep (mostly friction) this steep increase in friction head as system flow increases, means that each pump will be running at a significantly higher head and the individual pump flows will be much less than in single operation. Overall, the change in flow will be small when additional pumps are switched on.

This may be frustrating if you want to increase or vary system flow by switching pumps on and off.

Conversely, this particular aspect of steep systems; such as long pipelines and closed loop recirculating systems; is very useful to pump users that need to maximise system reliability.

These users will often specify multiple combinations of pumps operating in parallel to minimise system disruption in the event of a pump failure.

Typically, in critical applications such as cooling water circuits, three pumps may be installed with the normal operating mode being two running in parallel and the third being a standby unit. If it becomes necessary to shut one of the operating pumps down, the remaining operating pump will still provide a high percentage of the system flow until the standby pump can be started.

Is parallel operation good for you?

Installing pumps to operate in parallel can be an excellent strategy.

It is however very important to understand the aim of the exercise.

Parallel pump installations are a great idea in the following circumstances:

- Where limited availability of sufficiently large pumps or limits on driver size or electrical starting current dictate the use of multiple pumps.

- When flow needs to be varied according to varying system demand and when the system resistance characteristic is reasonably "flat".

- Where the use of multiple combinations of pumps operating in parallel in a "steep" system resistance will minimise potential system disruption in the event of a pump failure.

Remember:

- It is most important that the zero flow or "shut valve" heads are matched for pumps that are to operate together in parallel.

- Unstable pump curves must be avoided for parallel operation.

- Steeper pump curves are preferred for parallel operation.

- Be aware of minor performance variations that may change the suitability of otherwise well matched pumps.

Most important of all; understand your system.